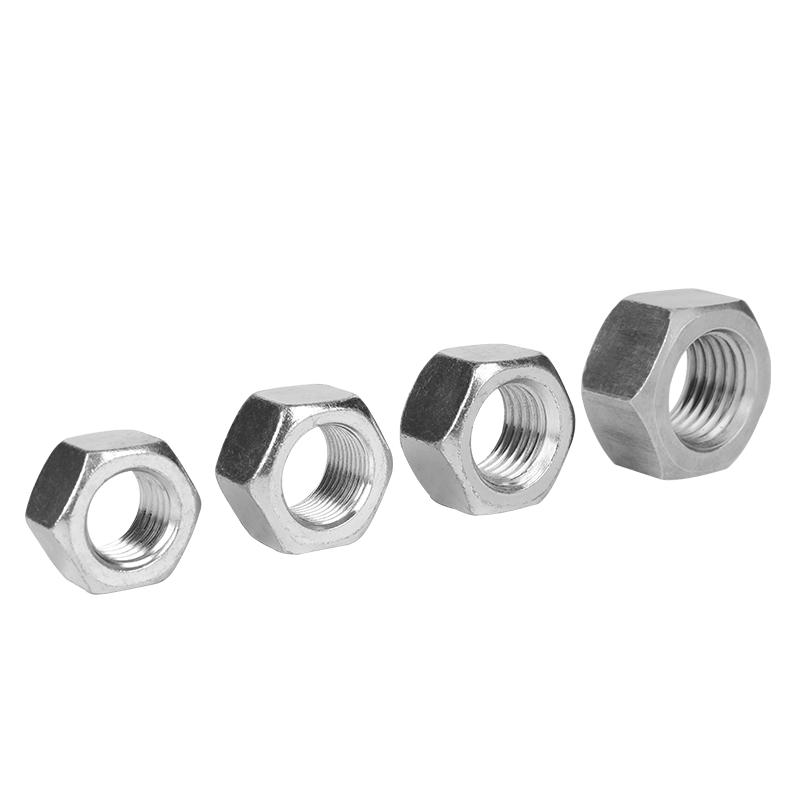

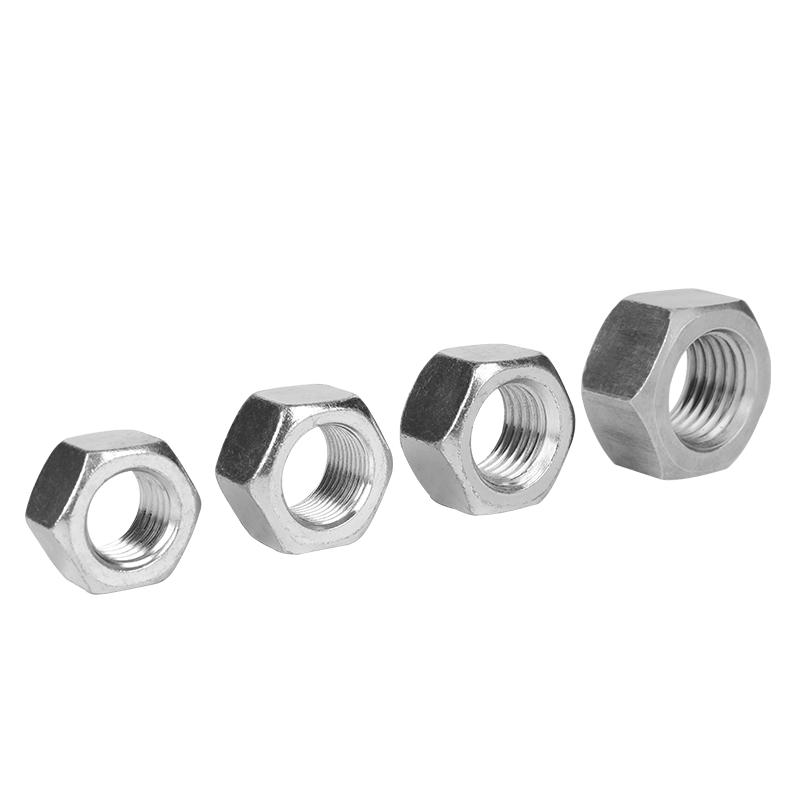

Hex nuts are one of the most widely used fasteners across industries due to their versatility, strength, and ease of installation. Whether in marine environments, automotive applications, or general construction, hex nuts provide reliable threaded fastening when paired with bolts. This article explores the different types of hex nuts, their material specifications, and size charts for various applications.

1/4-2" M3-M36 General Purpose Hex Nuts

Marine environments demand corrosion-resistant fasteners to withstand saltwater exposure. Stainless steel hex nuts (Grade 316) are ideal for boats, docks, and offshore structures due to their high resistance to rust and pitting. These nuts are commonly used in:

Shipbuilding and repair

Dock and pier construction

Underwater equipment assemblies

For maximum durability, marine-grade hex nuts should be paired with 316 stainless steel bolts and regularly inspected for wear.

Automotive manufacturing relies on high-strength hex nuts to secure critical components. Common types include:

Flange hex nuts – Reduce loosening from vibrations

Nylon insert lock nuts – Prevent self-release in high-movement parts

Grade 8 hex nuts – Used in suspension and engine assemblies

Heat-treated alloy steel nuts are preferred for high-stress areas, while coated variants prevent galvanic corrosion in aluminum parts.

Choosing the right hex nut size ensures proper fit and load distribution. Below is a quick reference for standard metric hex nut dimensions:

| Size (M) |

Width Across Flats (mm) |

Height (mm) |

| M4 |

7 |

3.2 |

| M6 |

10 |

5 |

| M8 |

13 |

6.5 |

| M10 |

17 |

8 |

| M12 |

19 |

10 |

For heavy-duty applications, consider thick hex nuts (DIN 934) or heavy hex nuts (ASME B18.2.2).

English

English

Español

Español