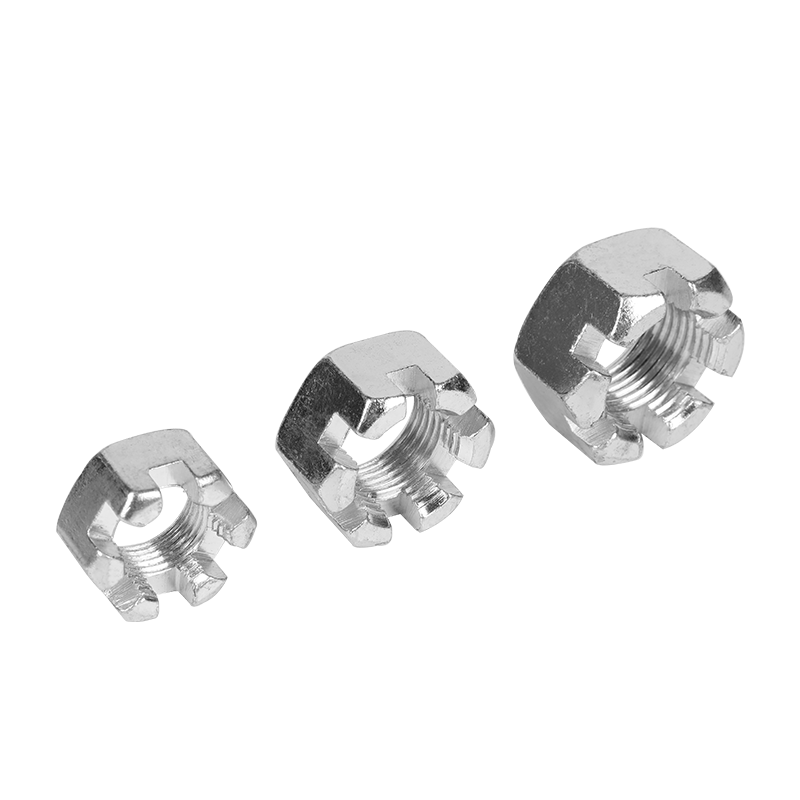

Can the use of Metal Lock Nuts effectively improve the stability and safety of component connections?

read more

In the automobile manufacturing industry, how to ensure that the bolt connection...

2024-05-09

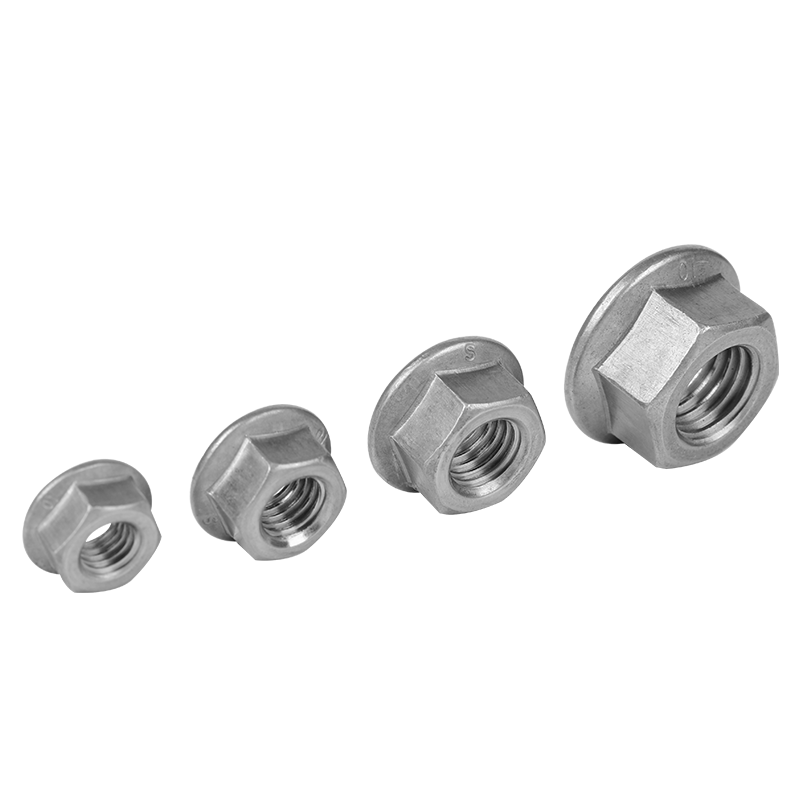

In the automotive manufacturing industry, how do flange nuts help ensure vehicle stability and safety?

read more

In the automotive manufacturing industry, flange nuts play a key role in ensurin...

2024-05-02

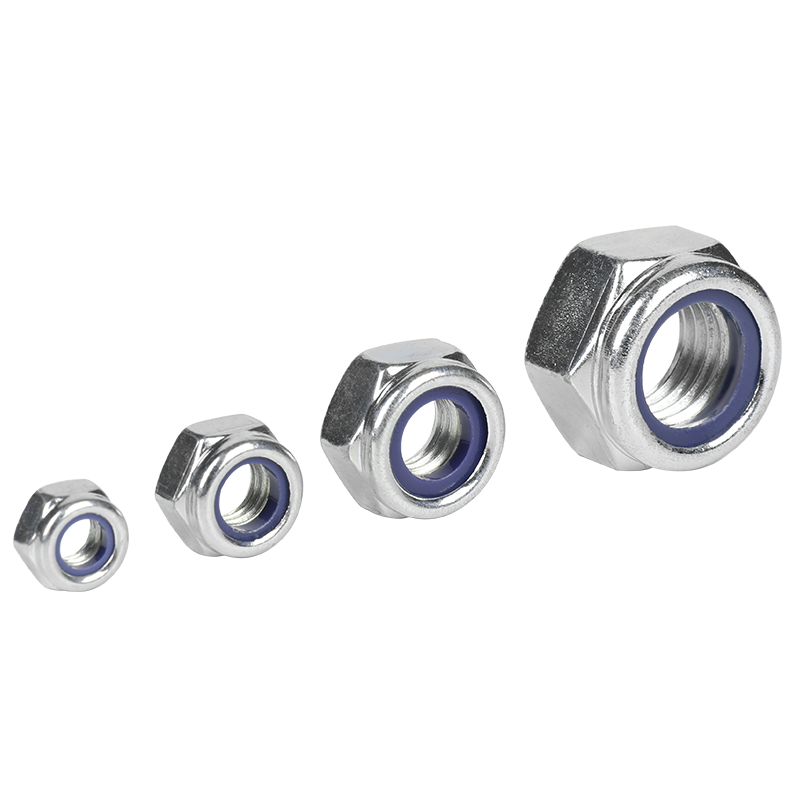

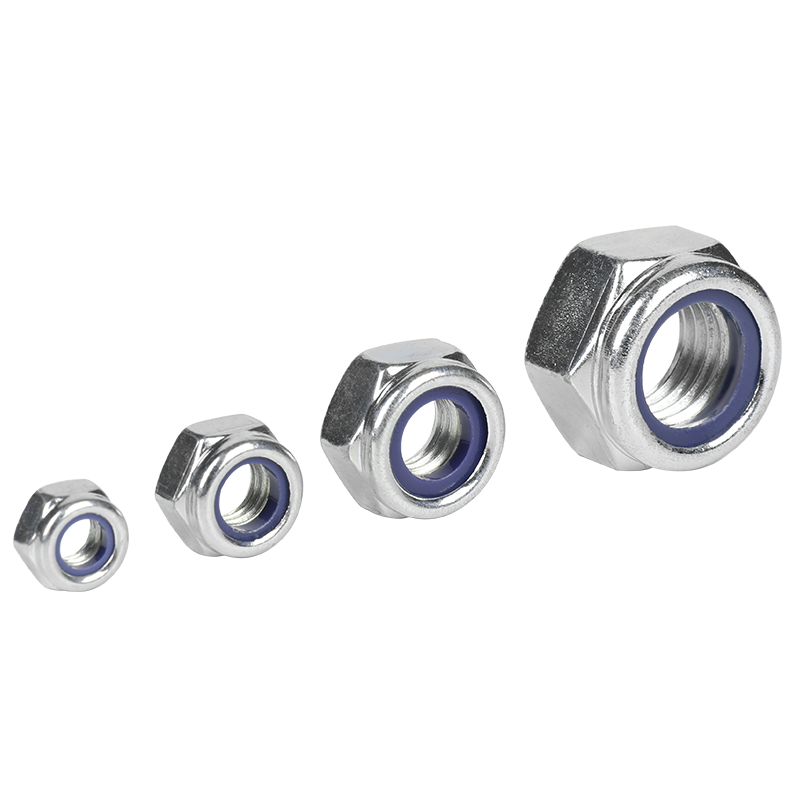

The Versatile Applications and Advantages of Non-Metal Insert Nylon Lock Nuts

read more

In various industries, the use of non-metal insert nylon lock nuts has become in...

2024-04-25

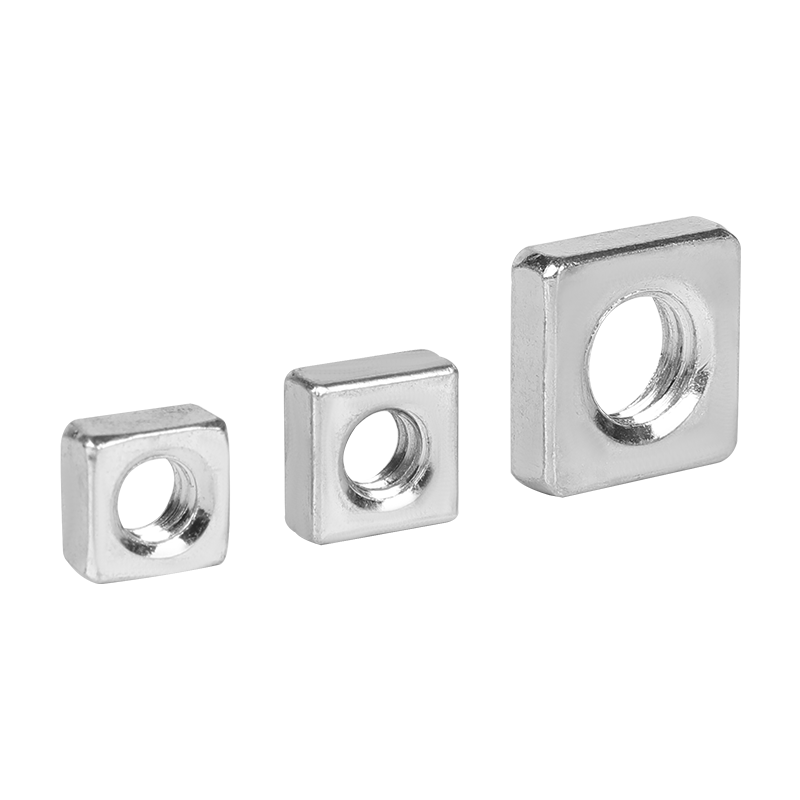

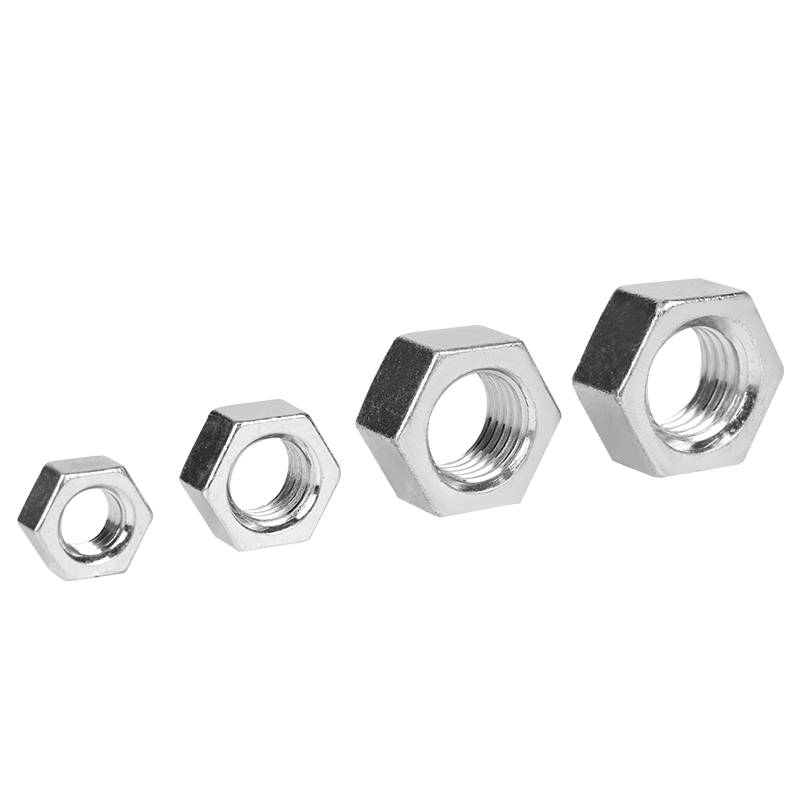

Ensuring Dimensional Accuracy of Single Chamfered Hexagon Nuts in the Manufacturing Process

read more

In industrial production, single chamfered hexagon nuts are common fasteners, an...

2024-04-18

English

English

Español

Español