Nuts are fasteners that work in conjunction with bolts to secure materials together. They are typically installed using a socket wrench and can be tightened or loosened by twisting them. Though most nuts work in the same way, they have many different designs that differ from one another. One type, known as a Flange Nut, features a protruding rim that helps distribute the load more evenly. Flange nuts are often used in applications involving oversized holes. They can also be useful when working in confined spaces because their flange design makes them less likely to drop out of the hole.

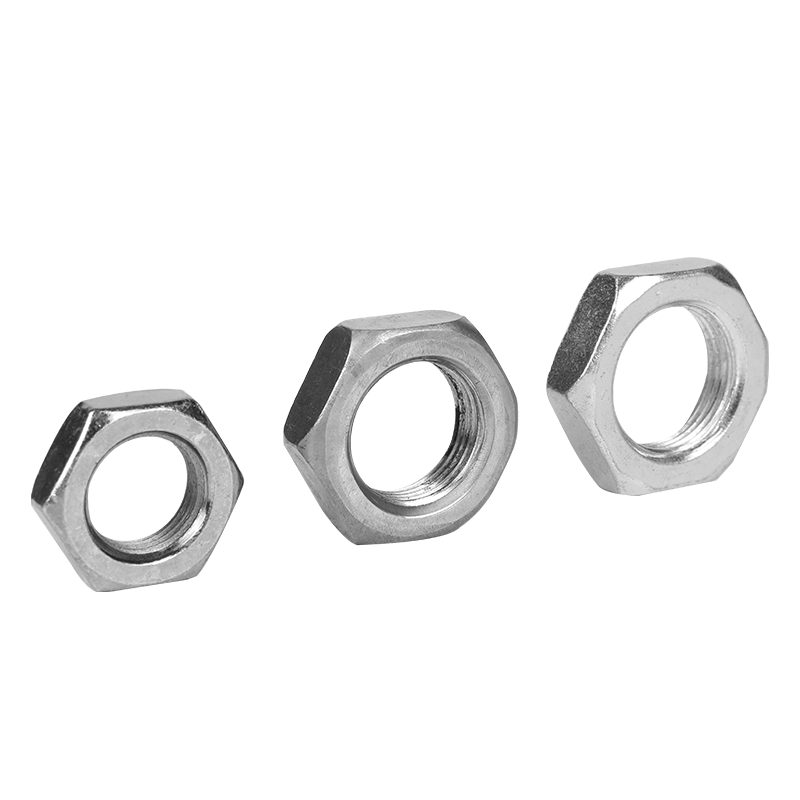

Hex Flange Iron Nuts are available in several different sizes and material compositions to suit a variety of fastening applications. They are usually made from steel or zinc coated to resist corrosion and ensure a strong, durable connection. They can be found in a wide variety of applications, including automotive and industrial manufacturing.

The protruding rim on a flange nut acts as a built-in washer, distributing the fastener's load over a wider surface area. This reduces stress on the threaded portion of the fastener and helps protect the mating surfaces from damage. Some flange nuts have serrations, which can help prevent loosening over time.

Since a flange nut eliminates the need for a separate washer, it saves valuable space in assembly lines. This can improve productivity and speed up operations. A flange nut is also less likely to loosen over time because its serrations bite into the material being fastened, preventing it from slipping off.

Some flange nuts feature an integrated lock. This design is sometimes referred to as a Prevailing Torque Lock Nut, because it requires the use of a wrench to apply a predetermined torque to the nut. These nuts provide greater security than traditional hex nuts, and they are ideal for use in high-stress applications where vibrations could cause the nut to loosen over time.

Other flange nuts are designed with a smooth surface, which allows them to slide over the threads of the bolt easily. These flange nuts are more flexible than other types of nuts, and they can be used in applications where the fastener needs to move freely, such as a machine or automobile.

The flange on a hex flange nut sits snugly against the edge of the socket wrench, preventing it from sliding down into the socket and falling out. This prevents the need for a second person to hold the socket, which can be useful when working in tight or confined spaces. This design is also helpful for those who have limited hand strength, because it can be easier to reach hard-to-get-to areas with a flange nut. In addition, it's almost impossible for a flange nut to accidentally drop out of the socket wrench while being tightened or loosened. This can make it a safer choice for use in children's toys and other items that require fasteners with a low-torque capacity.