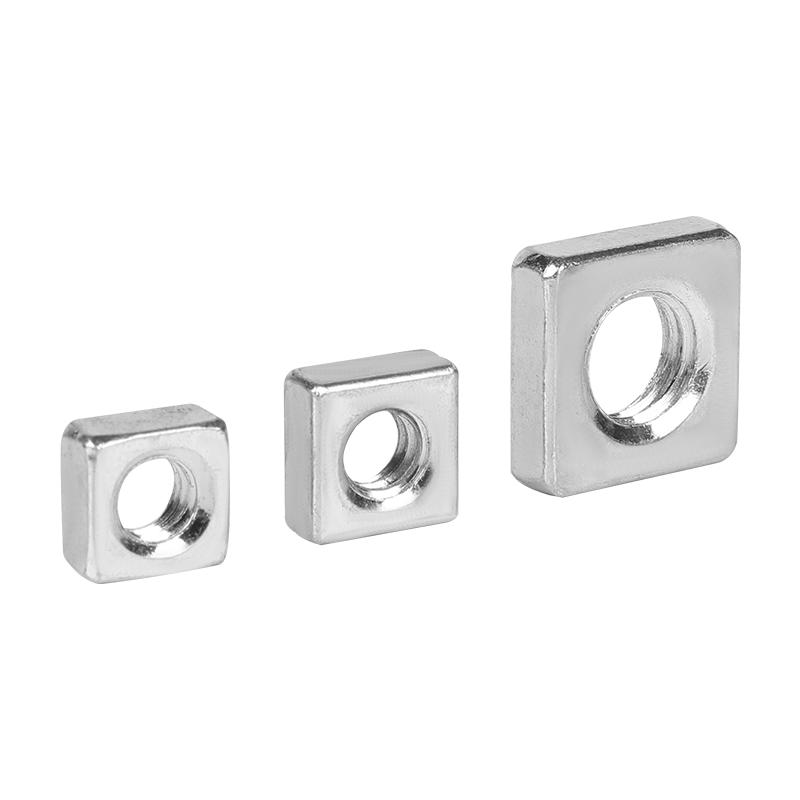

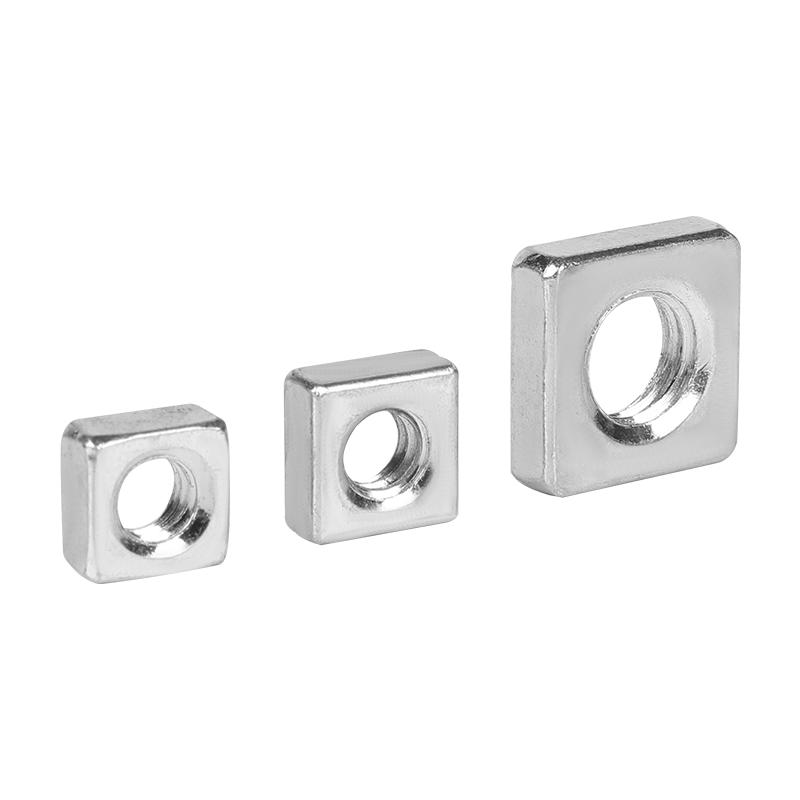

Square nuts, as a common type of fastener, have significant implications for various industries depending on their material selection. First and foremost, the corrosion resistance of square nuts is crucial for many industries. In applications exposed to moist or corrosive environments such as marine engineering, chemical industry, and maritime shipping, selecting materials with excellent corrosion resistance is essential. Stainless steel is a common choice due to its superior corrosion resistance, enabling it to work for extended periods in humid environments without rusting. Additionally, galvanized steel is often chosen, as the zinc coating applied to the surface effectively enhances its corrosion resistance. The selection of these materials can effectively prolong the service life of square nuts, ensuring the stability and safety of equipment and structures.

Secondly, the strength and hardness of square nuts vary depending on the requirements of different industries. In the automotive and aerospace industries, square nuts often need to withstand high levels of pressure and vibration, necessitating high-strength alloys or stainless steel materials. These materials not only possess excellent strength and hardness but also maintain stable performance under extreme conditions, ensuring the safe operation of equipment.

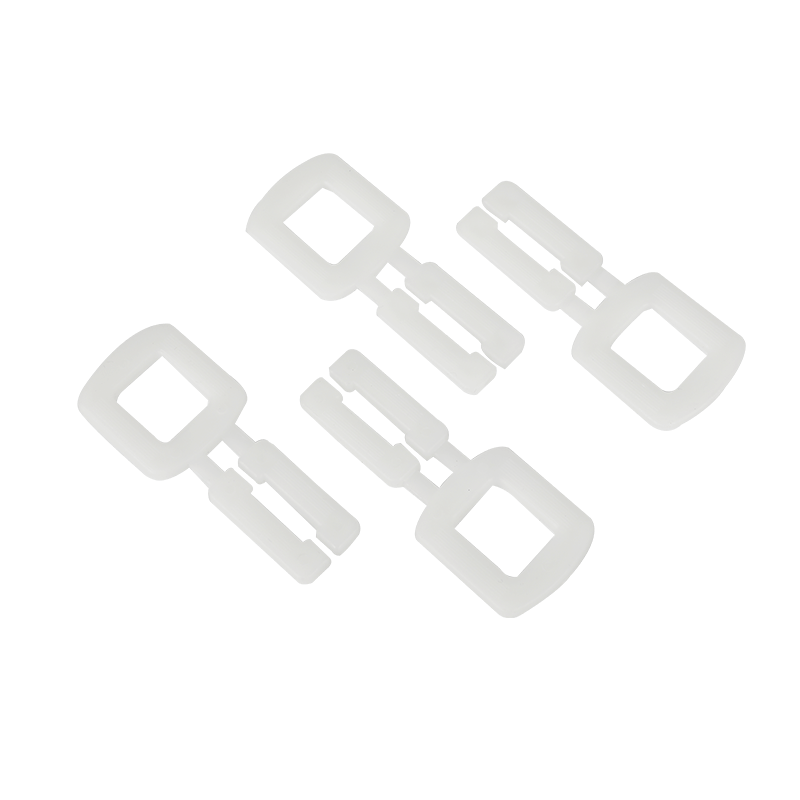

Lastly, the conductivity and insulation of square nuts are crucial in the field of electronics and electrical engineering. In these industries, material selection for square nuts needs to consider their conductivity or insulation properties. For instance, in situations requiring electrical grounding, materials capable of conducting electricity, such as copper or copper alloys, are usually selected. Conversely, in scenarios requiring insulation, materials like insulated plastic or ceramics may be chosen to avoid safety issues such as short circuits or electrical leakage in electrical equipment.

The material selection for square nuts has significant implications for various industry applications. By addressing requirements such as corrosion resistance, strength, and hardness, as well as conductivity and insulation, choosing suitable materials ensures that square nuts perform optimally in different working environments, safeguarding the stability and safety of equipment and structures. Therefore, when selecting materials for square nuts, it is essential to fully consider specific application requirements and choose materials accordingly to ensure their effective application across industries.