In the automobile manufacturing industry, how to ensure that the bolt connections of key components such as the engine and chassis do not loosen during high-speed driving and complex road conditions? Can the use of

Metal Lock Nuts effectively improve the stability and security of the connection of these components?

In the automobile manufacturing industry, it is crucial to ensure that the bolted connections of key components such as the engine and chassis do not loosen during high-speed driving and complex road conditions. Here are some ways to ensure the stability of your bolted joints, and considerations for using Metal Lock Nuts:

Choose high-quality bolts:

Choose bolts that meet or exceed industry standards, which typically offer greater strength and durability.

Give priority to bolts made of high-quality materials (such as stainless steel, alloy steel) to improve their fatigue resistance and corrosion resistance.

Precise control of tightening torque:

Use professional tightening tools and equipment to ensure that the bolts reach the specified tightening torque during assembly.

Tightening torque that is too small or too large may cause an unstable connection, so it must be precisely controlled.

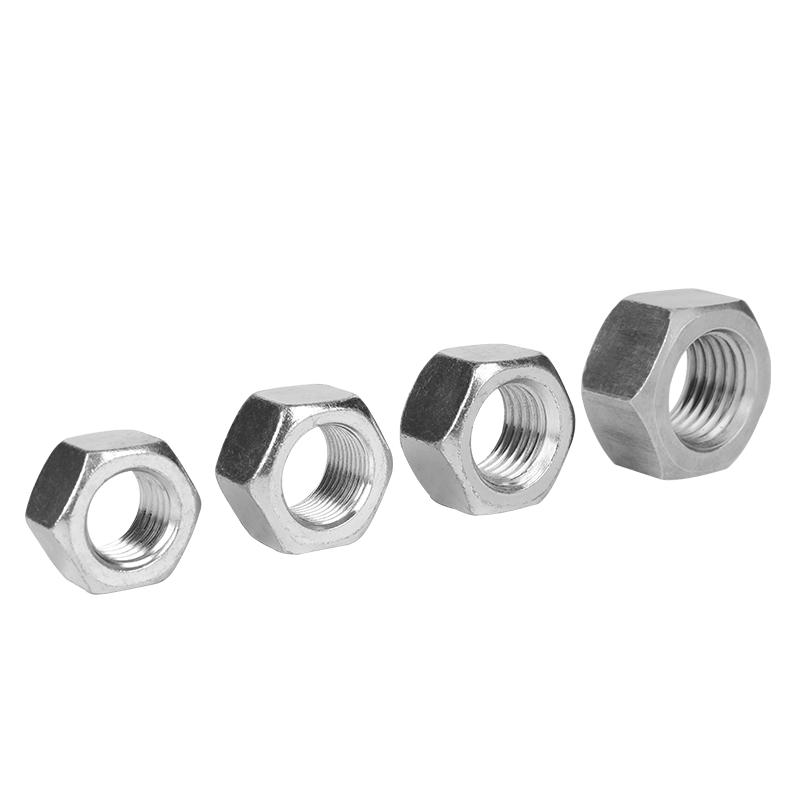

Use locking technology:

Various locking techniques can be used to enhance the stability of bolted connections, such as locking washers, locking glue or special locking nuts.

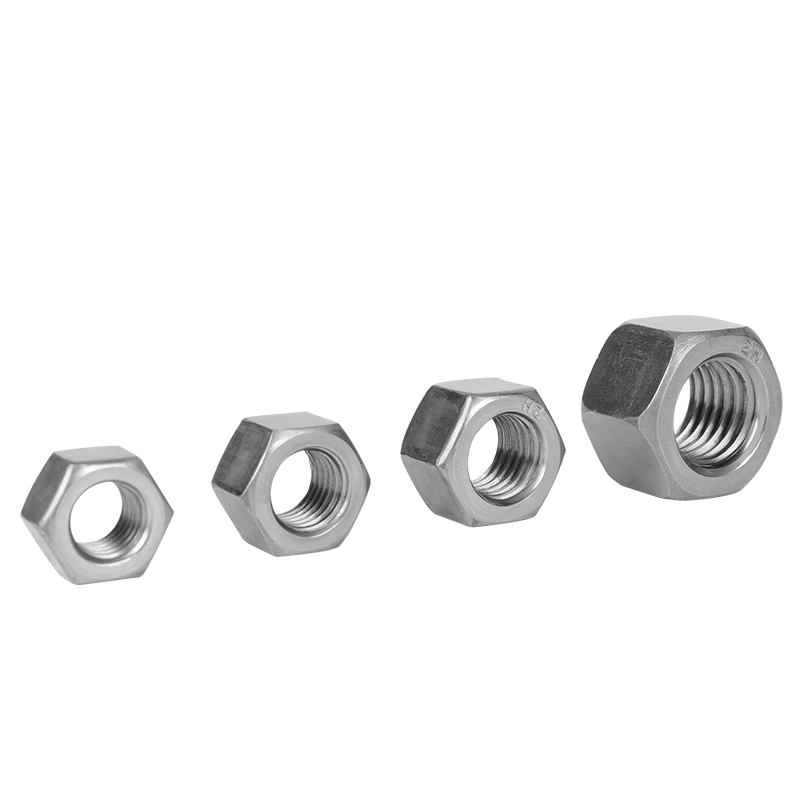

Metal Lock Nuts are an effective locking technology that uses a special structural design to create additional friction between the nut and bolt to prevent loosening. The stability and security of bolted joints can be significantly improved with Metal Lock Nuts.

Regular inspection and maintenance:

Even with high-quality materials and precise tightening torques, bolted connections can loosen due to long-term use, vibration, or impact.

Therefore, the key components of the car should be inspected and maintained regularly, and loose bolt connections should be discovered and repaired in time.

Optimization of design and manufacturing processes:

Consider the stability and safety of bolted connections during the design and manufacturing process, such as improving the strength and durability of bolts by optimizing thread design, selecting appropriate materials and heat treatment processes, etc.

Training and technical support:

Provide professional training to assembly workers to ensure they master correct bolt tightening methods and tool usage skills.

Provide technical support and problem solving to deal with various problems and challenges that may arise during the bolting process.

By using high-quality bolts, precisely controlling tightening torque, adopting locking technology (such as Metal Lock Nuts), regular inspection and maintenance, and optimizing the design and manufacturing process, the bolted connections of key components such as the automobile engine and chassis can be ensured to operate at high speeds and maintain stability in complex road conditions. At the same time, using Metal Lock Nuts as an effective locking technology can further improve the stability and safety of the connection of these components.

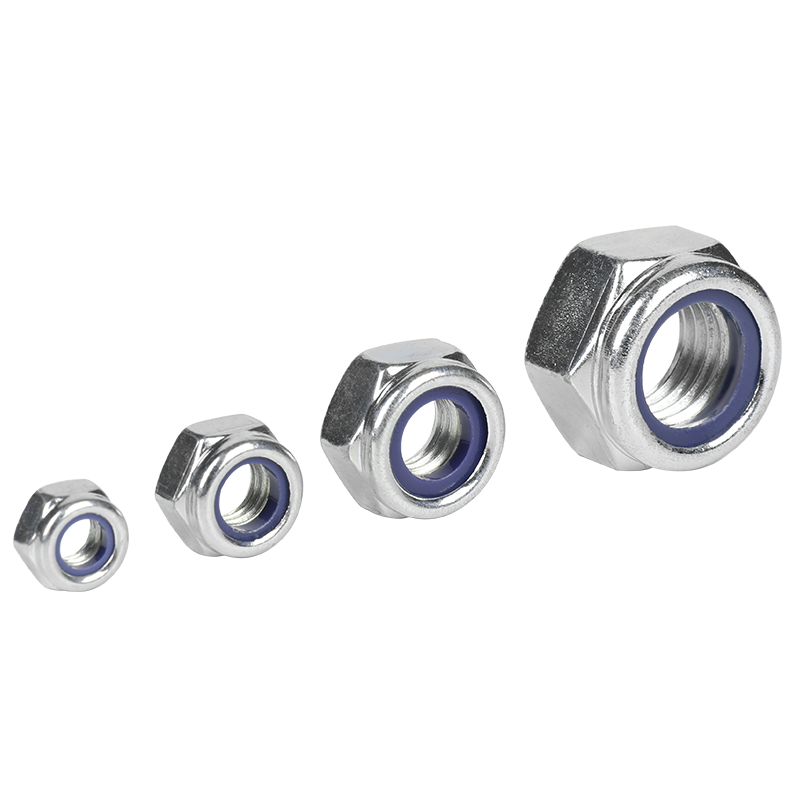

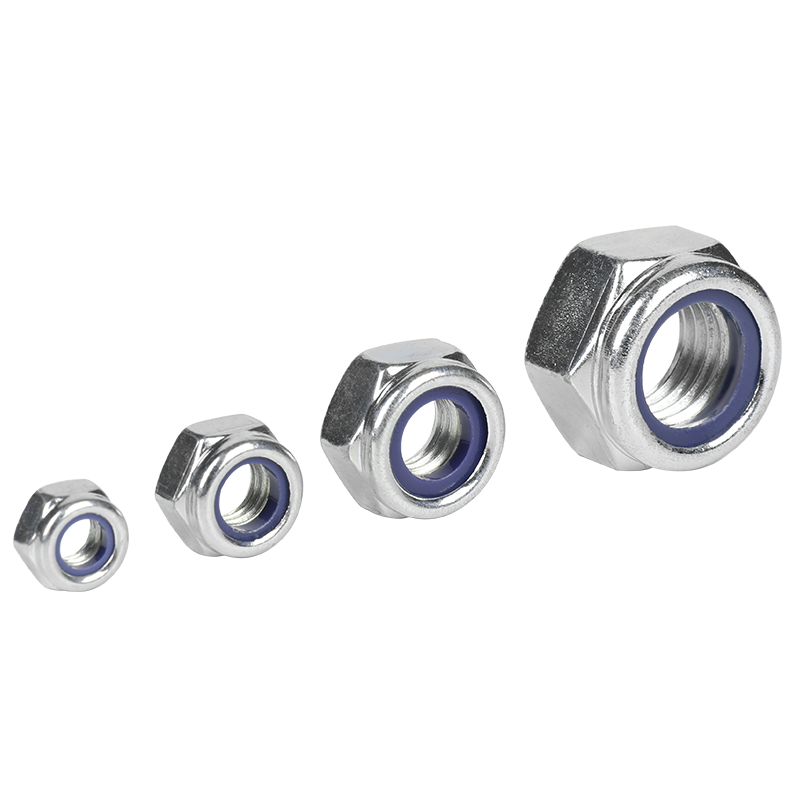

Non-Metallic Insert Nylon Lock Nuts

Non-Metallic Insert Nylon Lock Nuts