|

Standards: |

ASME/ANSI DIN ISO CNS |

|

Size |

1/4 -1.1/2 M3-M36 |

|

Surface treatment |

Original color, |

|

Material |

Carbon steel, stainless steel |

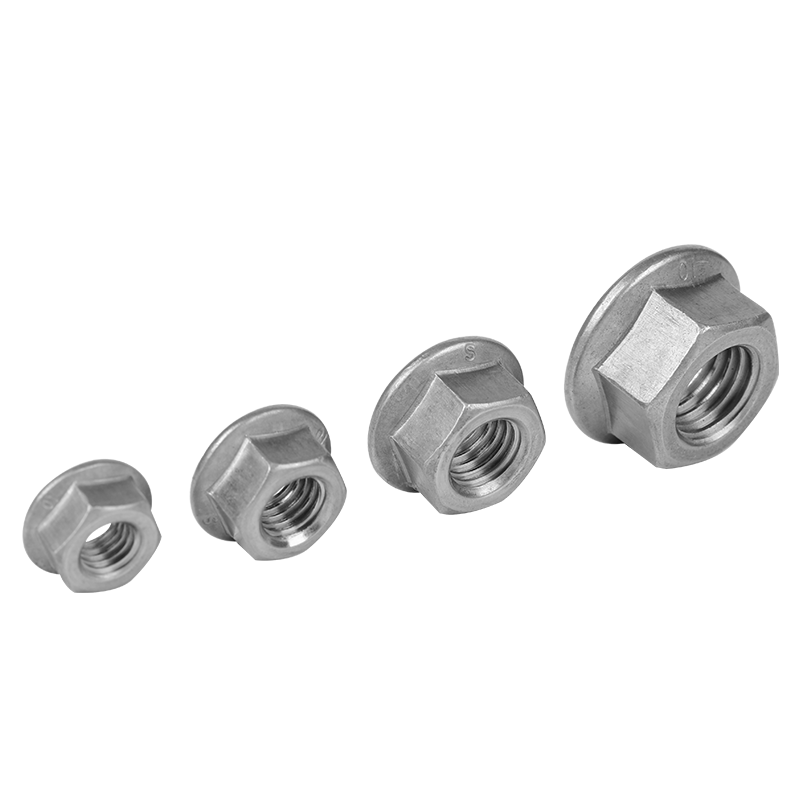

The non-metallic insert nylon lock nut is an upgraded version of the ordinary hexagonal nut. It has an extra non-metallic insert, and nylon is generally used as the medium. After the cold heading and tapping process is completed, a pressing process will be added, that is, a section of nylon ring without internal thread is pressed into the top of the metal nut to make it a whole. Due to the addition of the nylon ring, when the bolt is screwed into contact with the nylon ring, the resistance generated eliminates the gap on the side of the thread, causing a certain frictional resistance on the side of the thread, so that the anti-rotation force of the nut also increases accordingly, plus the nylon material. The characteristics of fatigue resistance and vibration absorption can effectively control the swing of the bolts and make the bolts not easy to loosen.

Our Nylon Locking Nuts with Non-Metallic Inserts are engineered to provide superior vibration resistance and long-lasting locking performance. Ideal for automotive, mechanical and industrial applications, these locking nuts feature a nylon insert that creates friction with the bolt threads to prevent loosening under dynamic loads.

Product Benefits

Vibration Resistant – Nylon inserts ensure a tight grip to prevent loosening caused by vibration and shock.

Corrosion Resistant – Non-Metallic Inserts eliminate the risk of galvanic corrosion when dissimilar metals are used.

Lightweight and Durable – Nylon material reduces weight without sacrificing strength.

Reusable – Can be reused multiple times without significantly decreasing locking performance.

Wide Temperature Range – Reliable operation in temperatures from -40°F to +250°F (-40°C to +121°C).

Technical Parameters

Material: Carbon steel (5/8 grade) or stainless steel (A2/A4) with nylon insert

Thread standards: Metric (M3-M20) and Imperial (1/4-3/4")

Surface treatment: Galvanized, blackened or natural stainless steel

Tightening torque: Meets DIN 985, ISO 7040 and ANSI/ASME standards

Applications

✔ Automotive and Aerospace – Engine components, chassis and critical assemblies

✔ Industrial Machinery – Conveyors, pumps and heavy equipment

✔ Electronics and Appliances – Prevent loosening in high vibration environments

✔ Construction and Infrastructure – Reliable fastening of structural and mechanical joints

Why choose our nylon lock nuts?

High-quality materials – Precision engineered to ensure maximum durability.

Strictly tested – Each batch is tested for vibration and torque.

Affordable prices – Order in bulk for economical and fast delivery.

Customized solutions – Special sizes, coatings and packaging available.

Frequently Asked Questions (FAQ)

Q: Can these locking nuts be used in high temperature environments?

A: Yes, our nylon insert locking nuts can work reliably in temperatures up to 121°C (250°F).

Q: Can they be reused?

A: Yes, they can be reused multiple times while maintaining the locking effect.

Q: Do you provide certifications?

A: We can provide RoHS, ISO 9001 and material test reports upon request.

Request a Quote Now

Contact Us: [+86-15757311052]

Email: [[email protected]]

Production Experience

Technical Staff

Annual Output

Follow Our News

Provide you with the latest enterprise and industry news.