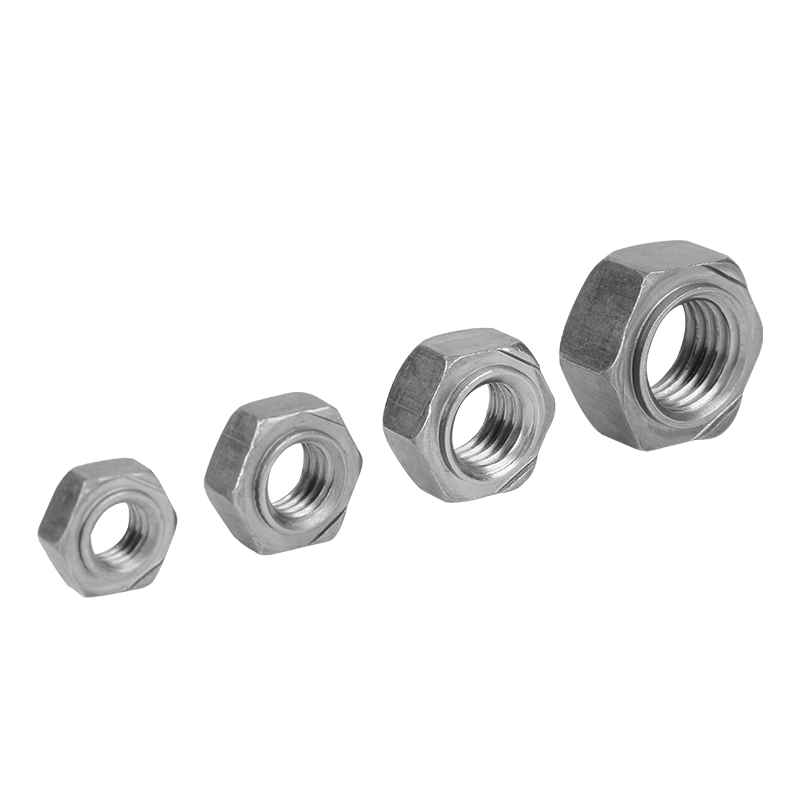

In industrial production, single chamfered hexagon nuts are common fasteners, and their dimensional accuracy directly affects the quality and performance of products. Therefore, ensuring their dimensional accuracy is crucial in the manufacturing process.

Firstly, strict process control is the foundation of ensuring the dimensional accuracy of single chamfered hexagon nuts. During the production process, strict control is needed for mold manufacturing, material selection, molding process, and other aspects. Firstly, the quality of mold manufacturing directly affects the shape and size of the product. Therefore, high-precision molds should be selected, and the manufacturing process should meet the specifications. Secondly, the selection of materials is also crucial. High-quality and stable performance raw materials should be chosen to ensure the mechanical properties and dimensional stability of the product. In addition, the control of the molding process is also crucial, and it is necessary to ensure that various parameters and process parameters during the molding process meet the design requirements to avoid dimensional deviations caused by process reasons.

Secondly, the application of precision machining equipment is one of the key steps to ensure the dimensional accuracy of single chamfered hexagon nuts. During the production process, high-precision machining equipment such as CNC machine tools and grinders are needed to ensure the dimensional accuracy of the product. CNC machine tools have the characteristics of high precision and efficiency and can meet the processing requirements of complex shapes and high precision, so they are often used in the production of single chamfered hexagon nuts. Grinders can achieve high requirements for product dimensions and surface accuracy. Through grinding, the dimensional accuracy and surface quality of the product can be effectively improved to ensure that the product meets the design requirements for dimensions and surface accuracy.

Lastly, regular inspection and adjustment are important means to ensure the dimensional accuracy of single chamfered hexagon nuts. During the production process, regular inspection and adjustment of machining equipment are needed to ensure their stable operation and reliable accuracy. This includes precision inspection and adjustment of CNC machine tools, grinders, as well as regular inspection and maintenance of molds and fixtures. Through regular inspection and adjustment, precision problems of machining equipment and molds can be discovered and corrected in a timely manner to ensure the dimensional accuracy of the product.

Through strict process control, precision machining equipment, and regular inspection and adjustment, the dimensional accuracy of single chamfered hexagon nuts can be effectively ensured, guaranteeing the quality and performance of the products. This not only requires requirements for production processes and equipment but also requirements for the quality management system of production enterprises. Only by ensuring the dimensional accuracy of products can customer needs be met and the long-term development of enterprises be guaranteed.

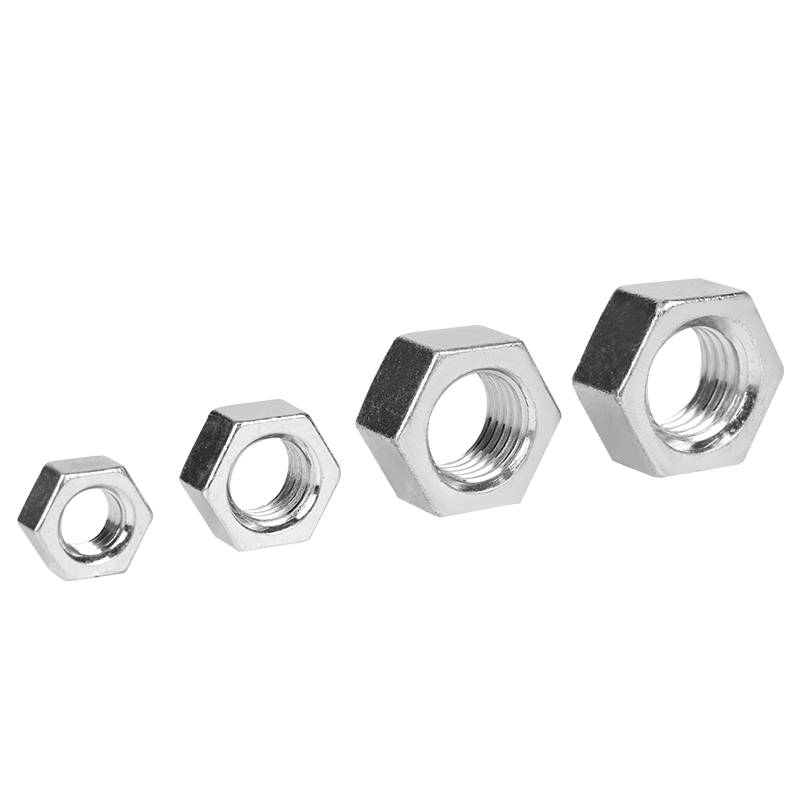

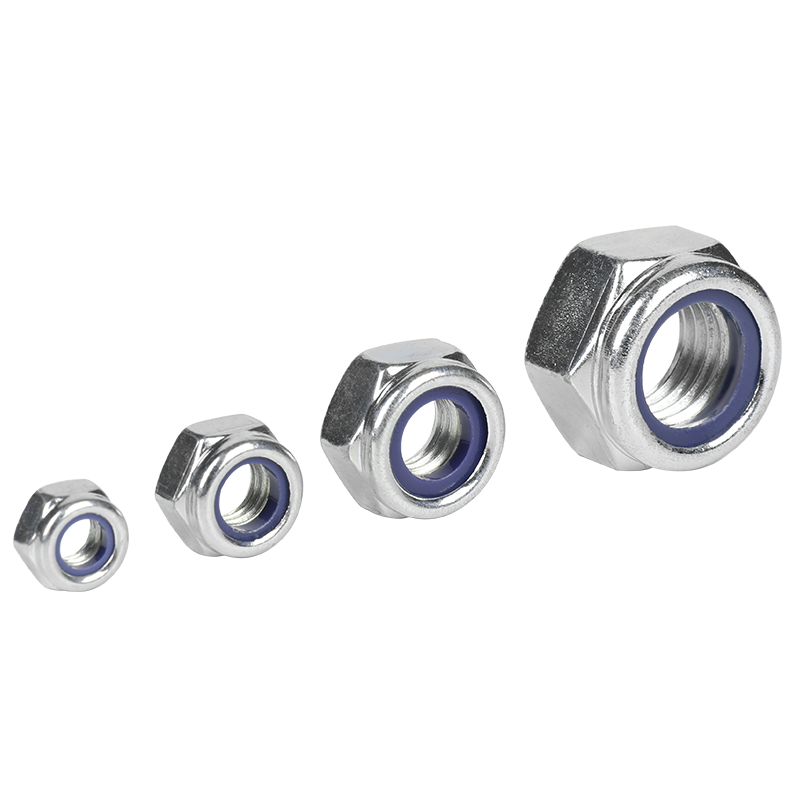

Single Chamfered Hexagon Nuts

English

English

Español

Español