Hexagon flange nuts, metal lock nuts, and slotted nuts are essential fasteners used across various industries, including automotive, construction, and machinery. Each type has unique features that make it suitable for specific applications.

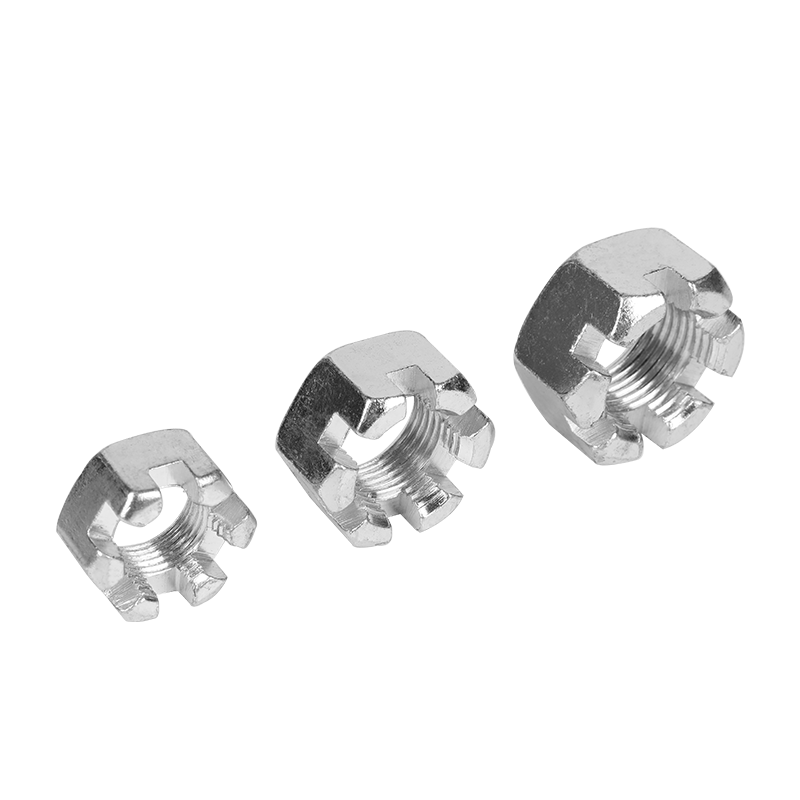

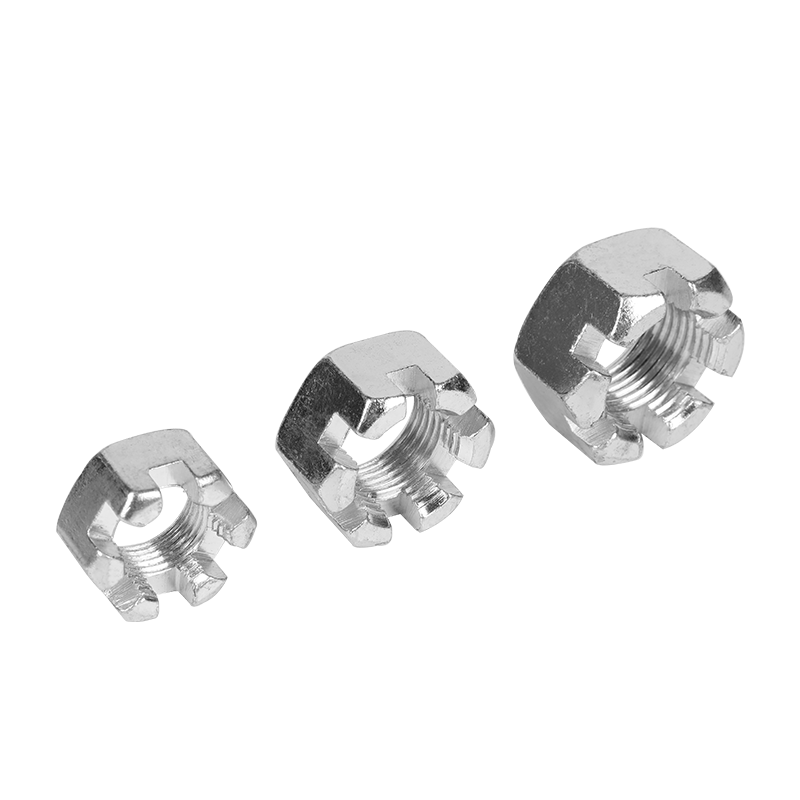

ASME/ANSI Stainless Steel Hexagon Slotted Nuts

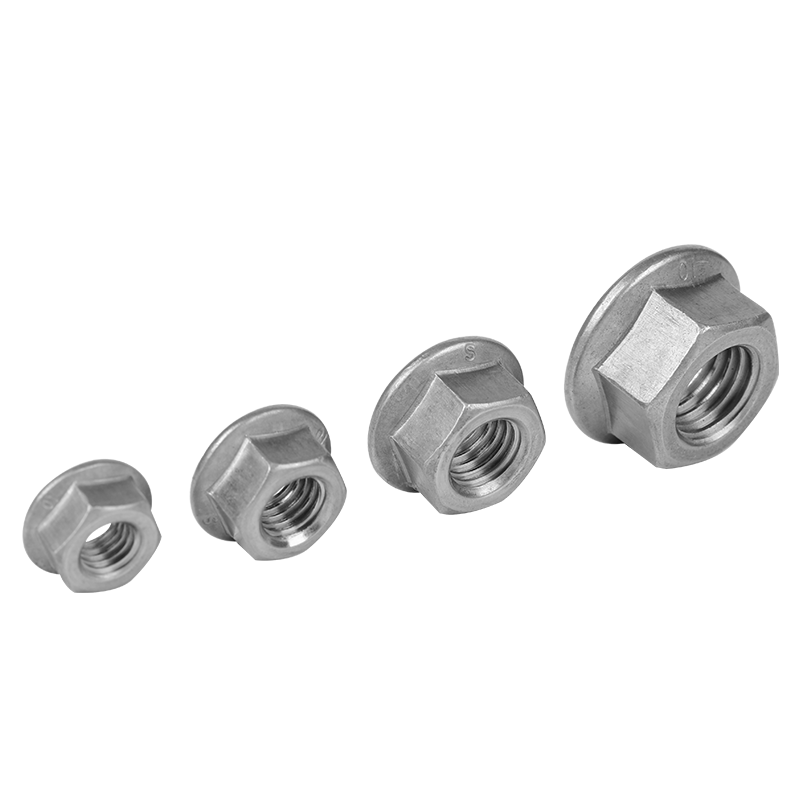

Hexagon flange nuts are characterized by their built-in washer-like flange, which distributes pressure and prevents loosening under vibration.

Key Features:

Integrated Flange: Eliminates the need for a separate washer.

Wide Bearing Surface: Reduces surface damage and improves load distribution.

Common Materials: Carbon steel, stainless steel, and brass.

Standard Sizes: M4 to M24 (metric) or #6 to 1" (imperial).

Applications:

Automotive assemblies

Structural steel connections

Heavy machinery

Comparison with Metal Lock Nuts and Slotted Nuts

| Feature |

Hexagon Flange Nuts |

Metal Lock Nuts |

Slotted Nuts |

| Locking Mechanism |

Flange distributes load |

Nylon insert or deformed threads |

Castellated top for cotter pins |

| Vibration Resistance |

Good |

Excellent |

Moderate |

| Reusability |

High |

Limited (nylon insert wears out) |

Moderate |

| Installation Speed |

Fast (no separate washer) |

Moderate |

Requires cotter pin |

| Common Applications |

General fastening |

High-vibration environments |

Shaft and axle securing |

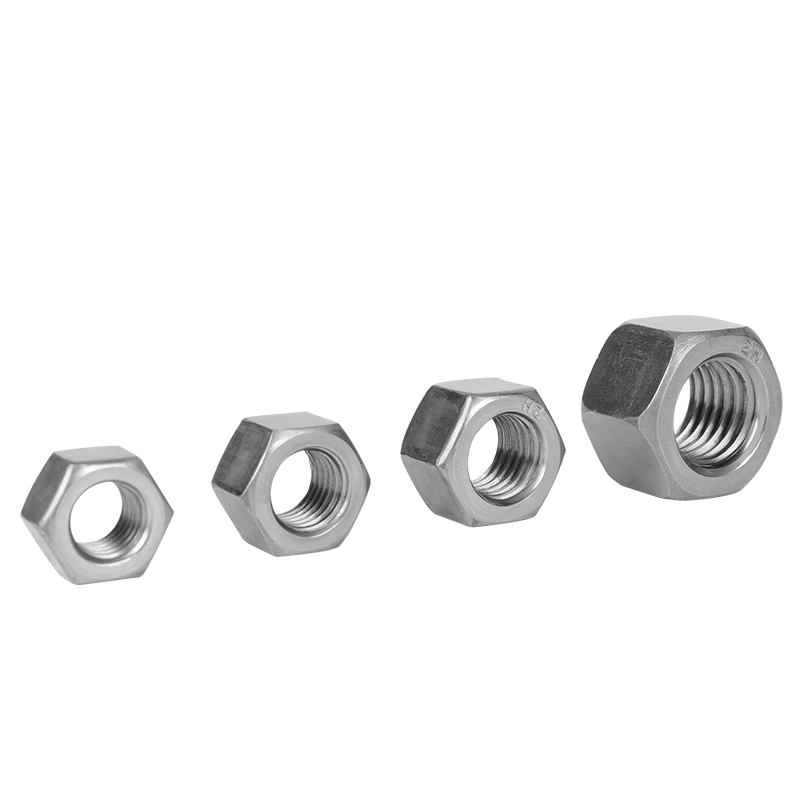

Metal Lock Nuts: Enhanced Vibration Resistance

Metal lock nuts use a nylon insert or deformed threads to prevent loosening. They are ideal for high-vibration environments but may have limited reusability.

Slotted Nuts: Secure Fastening with Cotter Pins

Slotted nuts (or castle nuts) have grooves for cotter pins, ensuring a secure fit in rotating assemblies like axles and shafts.

English

English

Español

Español