|

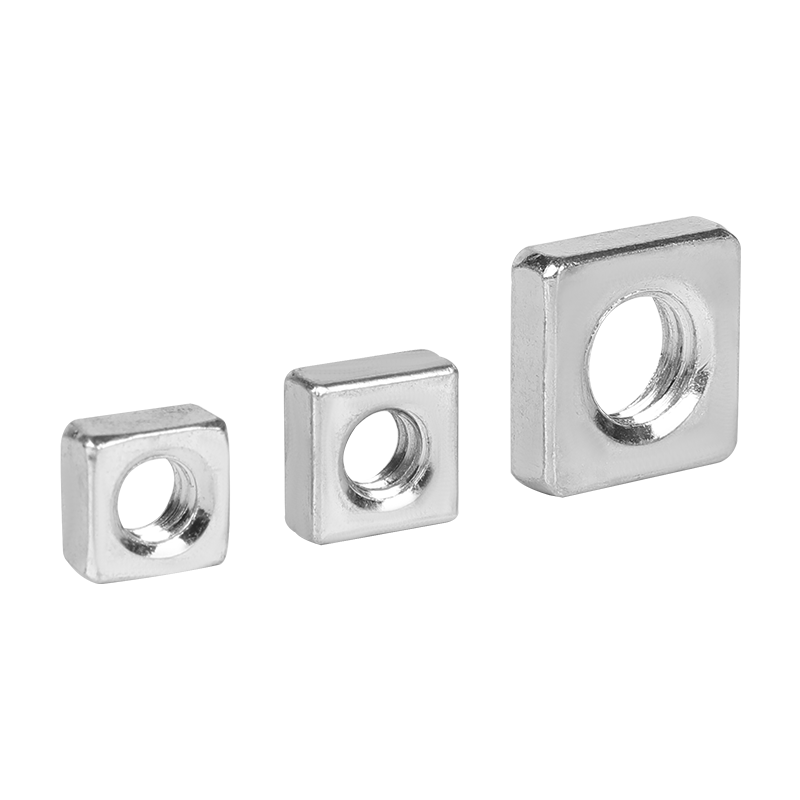

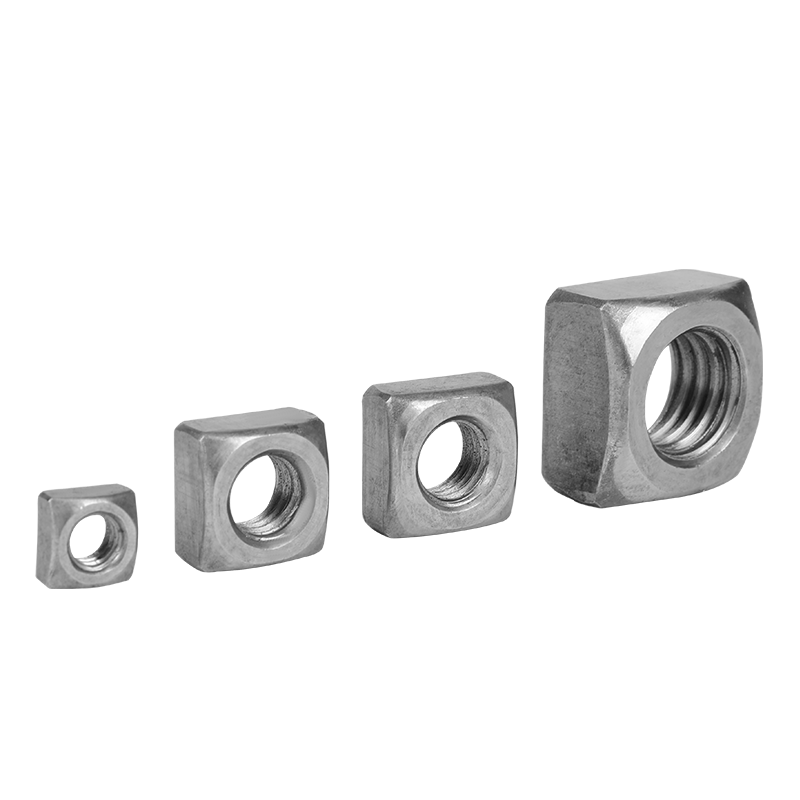

Standards: |

ASME/ANSI DIN |

|

Size |

1/4-1 M5-M10 |

|

Surface treatment |

Zinc-plated, black, dacromet |

|

Material |

Carbon steel |

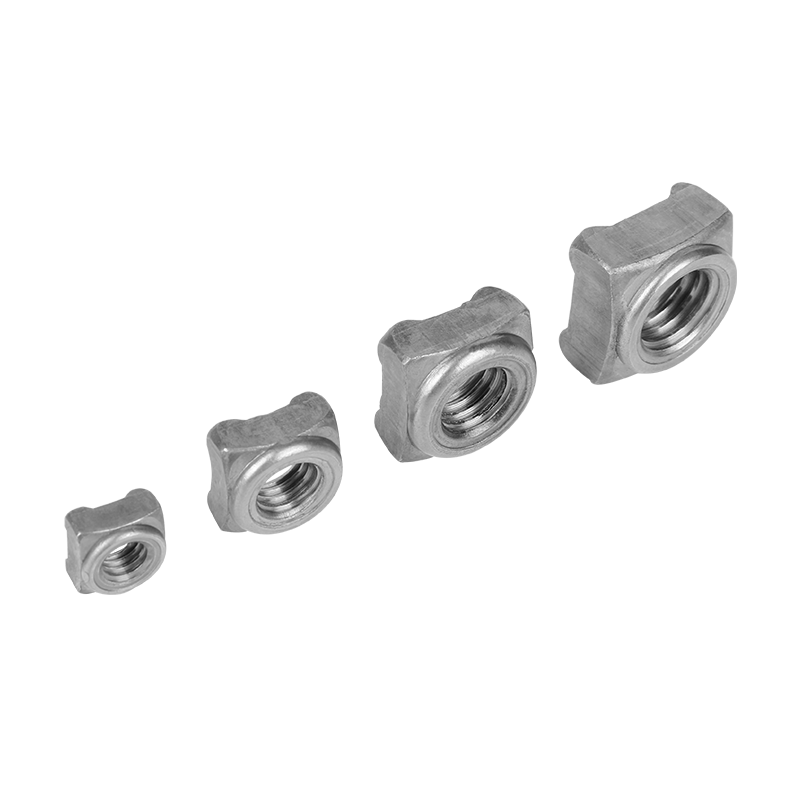

A slotted nut, also known as a castle nut, is a nut that has a slotted or notched design on one end. Slots or notches are used to accommodate cotter pins or set wires and help prevent nuts from loosening due to vibration or temperature changes. Slotted nuts are commonly used in applications requiring high security, such as automotive and machinery. Usually made of carbon steel and available in different sizes and strength classes. It should be noted that slotted nuts are not as common as other types of nuts and may not be used as frequently as other types of nuts such as hex nuts, heavy-duty nuts and lock nuts.

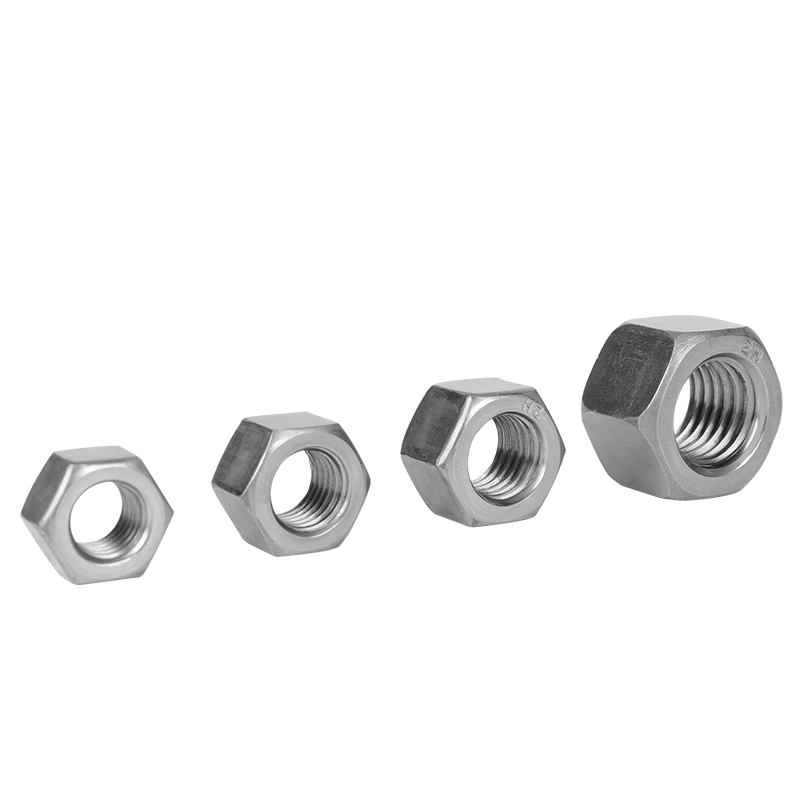

Our ASME/ANSI stainless steel hexagon slotted nuts are made of high-quality 304/316 stainless steel and strictly comply with ASME B18.2.2 and ANSI standards. They are suitable for highly corrosive environments, heavy-duty machinery and precision assembly requirements. The unique slot design provides reliable anti-loosening performance to ensure long-term stable connection.

Core advantages

Excellent corrosion resistance – 304/316 stainless steel material, suitable for harsh environments such as chemical, marine, and food processing.

Anti-loosening design – The hexagonal slot structure can be matched with pins or locking wires to prevent loosening caused by vibration.

High strength & durability – The heat treatment process is optimized, and the tensile strength reaches ≥80,000 PSI, far exceeding the industry standard.

Precise size compatibility – Meets ASME/ANSI standards and perfectly matches various bolts and screws.

Diverse applications – widely used in oil pipelines, marine equipment, aerospace and heavy machinery.

Typical application scenarios

Oil & gas pipelines – high pressure resistance, corrosion resistance, ensure long-term sealing of pipeline flanges.

Ship & marine engineering – 316 stainless steel resists salt spray corrosion and extends equipment life.

Food processing equipment – meets hygiene standards, easy to clean and pollution-free.

Rail transit – anti-loosening design ensures the stability of train chassis bolts.

Why choose us?

✔ 30 years of experience in fastener production – professional team provides technical support and customized services.

✔ Fast delivery – conventional specifications are shipped within 72 hours, and urgent orders are given priority.

✔ Quality assurance – each batch of products undergoes 100% hardness testing & size inspection.

✔ Global supply – cooperative customers are located in Europe, America, the Middle East, and Southeast Asia, and export packaging services are provided.

FAQ

Q: Do you support non-standard size customization?

A: Yes! Provide drawings or samples, and we can produce nuts with special threads, materials or surface treatments.

Q: How to choose between 316 and 304 stainless steel?

A: 316 contains molybdenum and is more suitable for high-chlorine environments (such as seawater); 304 is cost-effective and suitable for general industry.

Q: What is the minimum order quantity (MOQ)?

A: For detailed information on standard parts, customized parts, and minimum order quantity, please contact us.

Production Experience

Technical Staff

Annual Output

Follow Our News

Provide you with the latest enterprise and industry news.